- Keeps the implement on the guidance line, while allowing the tractor to travel off of it

- Straighter path for planting and strip tilling

- Use established guidance lines all season long

- Runs on either the Gen 4 4600 CommandCenter™ or the 4640 Universal Display

Features

Precisely place the row where it is supposed to be with AutoTrac™ Implement Guidance

Plant accurate rows

Plant accurate rowsThe goal of all producers is to have inputs, such as seed or fertilizer, placed into the ground in the most accurate way possible. With the increasing cost of inputs and adoption of farming practices that need precision, such as strip-till applications, accuracy at the implement has become increasingly important.

AutoTrac Implement Guidance helps maximize the use of inputs by increasing accuracy and repeatability at the implement thanks to a second receiver on the implement. Having a second StarFire™ receiver located on the implement allows the tractor to guide the implement through the field with additional accuracy, even on curved passes and sloping terrain. AutoTrac Implement Guidance (passive) commands the tractor to the correct location to keep the implement on the guidance line. In applications utilizing AutoTrac Implement Guidance, seeds are more consistently placed to take full advantage of pre-applied nutrients. This level of precision allows implement guidance to reduce overall input costs.

Maximize operational precision and accuracy

“Best thing I did was put implement guidance on my planter, I’m on the guess row and you can’t tell.” – Happy ATIG Customer in NE

Accurate implement positioning and maintaining a consistent distance between passes (often referred to as guess rows) is crucial for many growers. While differential corrections ensure tractor location accuracy, implement drift can reduce the location accuracy at the implement level. Enhancing pass-to-pass accuracy with AutoTrac Implement Guidance, improves overall operational accuracy throughout the crop year, enabling more effective use of the AutoTrac™ automated steering system on subsequent passes through the field. This also facilitates the use of implements with varying widths on the same field, such as using a 40-foot strip-till bar, followed by a 60-foot planter, and then a 120-foot sprayer.

ATIG allows the machine to automatically steer itself for implement consistency pass-to-pass

ATIG allows the machine to automatically steer itself for implement consistency pass-to-passAs previously noted, ATIG enables consistent guess rows, which reduces overlap and improves placement of inputs.

IMPORTANT NOTES:

- Performance when using ATIG on an articulated tractor may vary.

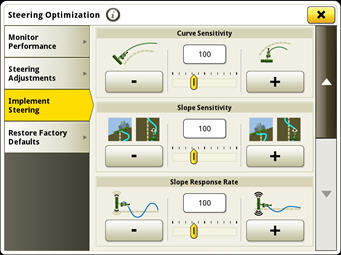

- When using ATIG in curves, the operator may need to adjust the curve sensitivity setting to improve system accuracy. This setting can be found in the Steering Optimization settings, as seen below. Make adjustments up or down, depending on the curve performance.

Advanced Settings to dial in desired performance

Advanced Settings to dial in desired performanceActive Implement Guidance vs. AutoTrac™ Implement Guidance

Active Implement Guidance

Active Implement Guidance AutoTrac Implement Guidance (passive)

AutoTrac Implement Guidance (passive)Active Implement Guidance (AIG) and AutoTrac Implement Guidance (Passive) (ATIG) allow operators to be more precise and productive in the work they are doing as they can focus on value-add tasks and let the system take care of the steering while traveling though the field.

So, what is the difference between AIG and ATIG? We are happy you asked:

Active Implement Guidance (AIG) pairs up with an implement steering mechanism, which allows both the implement and tractor to stay precisely on the same guidance track. This system is optimal for applications in standing row crops, like side-dressing application of nutrients, in addition to first-pass operations like planting and seeding or strip-tilling.

AutoTrac Implement Guidance (passive), on the other hand, allows the tractor to travel off the guidance track while keeping the implement on the intended path or guidance track. There is no implement steering mechanism needed because the tractor can travel off the guidance track. This system is optimal for first-pass applications like pre-season nutrient applications, tillage, planting and seeding, or strip-tilling. It is not recommended for applications in emerged crops or when planting in applications where the tractor must stay precisely on the guidance track.

G5 and Generation 4 compatibility chart

This document lists all the compatible equipment approved with the latest GenOS software and is subject to change with newer software updates. To ensure complete and proper compatibility, the most current version of implement control unit software, G5 or Generation 4 display software, and compatible farm management information software (FMIS) should be used. Non-current software versions will require an update before support can be provided.

Similarly, unapproved software version configurations will not be supported. Please note that the 17-2 software release was the last update that was compatible with 4600 CommandCenter™ displays with v1 processors. All software released after 17-2 are not compatible with 4600 CommandCenter display with v1 processors, these updates are compatible with like displays with v2 processors.

Server serial numbers are as follows:

- v1 = RWG prefix

- v2 = PCG prefix

Machine compatibility

John Deere Large Ag Tractors

| John Deere Large Ag Tractors (list of all automatically detected machines) | Model year | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

| 9R/9RT/9RX Series | 2024 and newer | X | --- | --- | X | X | X | X | X |

| 9R/9RT/9RX Series | 2018-2021 | X | --- | --- | --- | X | X | X | X |

| 9R/9RT/9RX Series | 2015-2017 | * | --- | --- | --- | X | X | X | X |

| 9R/9RT Series | 2012-2014 | --- | --- | --- | --- | X | X | X | X |

| 9030/9030T Series | 2008 and newer | --- | --- | --- | --- | X | X | X | X |

| 9020/9020T Series | 2002-2007 | --- | --- | --- | --- | X | --- | X | X |

| 9000 Series | 1997-2001 | --- | --- | --- | --- | X | --- | X | X |

| 9000T Series | 2000-2001 | --- | --- | --- | --- | X | --- | X | X |

| 8R/8RT/8RX Series | 2024 and newer | X | --- | --- | X | X | X | X | X |

| 8R/8RT Series | 2018-2020 | X | --- | --- | --- | X | X | X | X |

| 8R/8RT Series | Mid-2014 - 2017 | * | --- | --- | --- | X | X | X | X |

| 8R/8RT Series | 2010-2013 | --- | --- | --- | --- | X | X | X | X |

| 8030/8030T Series | 2006 and newer | --- | --- | --- | --- | X | X | X | X |

| 8020/8020T Series | 2002-2005 | --- | --- | --- | --- | X | --- | X | X |

| 8010/8010T Series | 2000-2002 | --- | --- | --- | --- | X | --- | X | X |

| 8000 Series | 1994-1999 | --- | --- | --- | --- | X | --- | X | X |

| 8000T Series | 1997-1999 | --- | --- | --- | --- | X | --- | X | X |

| 7R Series | 2024 and newer | X | X | X | X | X | X | X | X |

| 7R Series | 2018-2023 | X | X | --- | --- | X | X | X | X |

| 7R Series | 2014-2017 | * | --- | --- | --- | X | X | X | X |

| 7R Series | 2011-2013 | --- | --- | --- | --- | X | X | X | X |

| 7J Series | 2018 and newer | --- | --- | --- | --- | X | X | X | X |

| 7M Brazil | 2024 and newer | --- | --- | --- | --- | X | X | X | X |

| 7030 Series | 2007 and newer | --- | --- | --- | --- | X | X | X | X |

| 7030 Series (Large Frame) | 2007 and newer | --- | --- | --- | --- | X | X | X | X |

| 7030 Series (Small Frame) | 2006 and newer | --- | --- | --- | --- | X | X | X | X |

| 7020 Series | 2003-2007 | --- | --- | --- | --- | X | X | X | X |

| 6030 Series (Small Frame) | 2006 and newer | --- | --- | --- | --- | X | X | X | X |

| 6R Series | 2024 and newer | --- | --- | X | X | --- | --- | X | X |

| 6R Series | 2018-2023 | X | X | --- | --- | X | X | X | X |

| 6R Series (Final Tier 4) | 2015-2017 | * | --- | --- | --- | X | X | X | X |

| 6R Series (Interim Tier 4) | 2013-2015 | --- | --- | --- | --- | X | X | X | X |

| 6M Series | 2013 and newer | --- | --- | --- | --- | X | X | X | X |

| 6J Series | 2018 and newer | --- | --- | --- | --- | X | X | X | X |

| 5R Series | 2019 and newer | --- | --- | --- | --- | X | X | X | X |

*NOTE: For latest Precision Ag functionality, update machines equipped from the factory with v1 processor to v2.

John Deere Nutrient Applicators

John Deere Nutrient Applicators | Model year | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

| F4365 High-Capacity Nutrient Applicator | 2017 and newer | X | --- | --- | --- | --- | --- | --- | --- |

John Deere Self-Propelled Sprayers

| John Deere self- propelled sprayers | Model year | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

| 400 and 600 Series Sprayers/4023 | 2022 and newer | X | --- | --- | --- | --- | --- | --- | --- |

| 4 Series Sprayers | 2018 - 2021 | X | --- | --- | --- | --- | --- | --- | --- |

| 4 Series Sprayers | 2013 - 2017 | --- | --- | --- | --- | X** | --- | --- | X** |

| 4940 | 2012 - 2014 | --- | --- | --- | --- | X** | --- | --- | X** |

| 4630 | 2008 and newer | --- | --- | --- | --- | X** | --- | --- | X** |

| 4730 | 2008 and newer | --- | --- | --- | --- | X** | --- | --- | X** |

| 4830 | 2008 - 2014 | --- | --- | --- | --- | X** | --- | --- | X** |

| 4930 | 2008 - 2013 (serial number 4000+) | --- | --- | --- | --- | X** | --- | --- | X** |

| 4720, 4920 | 2004-2007 | --- | --- | --- | --- | X** | --- | --- | X** |

| Hagie™ sprayers | 2014 and newer | Compatible with GreenStar™ 3 2630 Displays and 4640 Universal Displays* | |||||||

*NOTE: When using the 4640 Universal Display on a Hagie Sprayer, additional mounting and harnessing may be required.

- 4640 RAM™ mount - SJ34503

- 4640 power/video harness - BPF11527 (1-3 video plus machine power), PF90687 (machine power only)

NOTE: Current John Deere/Hagie field kits only offer GreenStar 3 2630 Display parts.

NOTE: Multi-rank section control are not supported on Hagie at this time.

NOTE: VIN detection on Hagie Sprayers is only supported on model year 2019 and newer machines.

NOTE: 22-2 and newer software allows the Gen 4 4640 Universal Display to control the Hagie/Montag Fortifier configuration.

**NOTE: The 4640 Universal Display will replace the GreenStar 3 2630 Display on the armrest. Dual display with the GreenStar 3 2630 Display is not supported with sprayers. The 4640 Universal Display does not use the external display navigation buttons located on the armrest, so these buttons are disabled in this configuration.

John Deere Self-Propelled Forage Harvesters (SPFH)

John Deere SPFH | Model year | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

| 9000 Series SPFH | 2019 and newer | --- | --- | --- | --- | X | --- | --- | X |

| 8000 Series SPFH | 2015 and newer | --- | --- | --- | --- | X | --- | --- | X |

NOTE: When adding the 4640 Universal Display to a John Deere SPFH, it will only be compatible as a precision ag display and is installed on the side rail.

John Deere Combines

| John Deere Combines | Model year | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

| X9 Series | 2024 and newer | --- | --- | --- | X | --- | --- | --- | --- |

| X9 Series | 2021-2023 | X | --- | --- | --- | --- | --- | --- | --- |

| S700 Series | 2024 and newer | --- | --- | --- | X | --- | --- | --- | --- |

| S700 Series | 2018-2023 | X | --- | --- | --- | --- | --- | --- | --- |

| S430 and S440 | 2024 and newer | --- | --- | X | --- | --- | --- | --- | --- |

| S430 and S440 | 2017-2023 | X | --- | --- | --- | --- | --- | --- | --- |

| S600 Series | 2012 - 2017 | --- | --- | --- | --- | X* | X* | X* | X* |

| S540 and S550 Series | 2024 and newer | --- | --- | --- | --- | --- | --- | --- | X* |

| S540 and S550 Series | 2012-2023 | --- | --- | --- | --- | X* | X* | X* | X* |

| T-Series | 2012 and current | --- | --- | --- | --- | X* | X* | X* | X* |

| 70 Series | 2008 - 2013 | --- | --- | --- | --- | X* | X* | X* | X* |

| 60 Series | 2004 - 2007 | --- | --- | --- | --- | X* | --- | --- | X* |

| 50 Series | 2000 - 2003 | --- | --- | --- | --- | X* | --- | --- | X* |

NOTE: Competitive equipment may be compatible with 4640 Universal Display and 4240 Universal Display.

*NOTE: When adding the 4640 Universal Display to a John Deere combine, it will only be compatible as a cornerpost precision ag display.

NOTE: RowSense™ sensor voltage readings and sensor offsets are displayed on Original GreenStar Monitor emulator on 50, 60, and 70 Series Combines.

John Deere Cotton Harvesters

| John Deere Cotton Harvesters | Model year | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

| CP770 | 2024 and newer | --- | --- | --- | X | --- | --- | --- | --- |

| CP770 | 2022-2023 | X | --- | --- | --- | --- | --- | --- | --- |

| CS770 | 2024 and newer | --- | --- | --- | X | --- | --- | --- | --- |

| CS770 | 2022-2023 | X | --- | --- | --- | --- | --- | --- | --- |

| CP690 | 2015 and newer | --- | --- | --- | --- | X | --- | --- | X |

| CS690 | 2015 and newer | --- | --- | --- | --- | X | --- | --- | X |

NOTE: Update cab controller software to the latest version on model year 2017 and newer cotton harvesters to use Harvest Identification, Cotton Pro.

NOTE: When adding the 4640 Universal Display to a John Deere Cotton Harvester, it will only be compatible as a cornerpost precision ag display.

John Deere Self-Propelled Windrowers

John Deere Self-Propelled | Model year | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

| W235 | 2014 and newer | --- | --- | --- | --- | X | X | X | X |

| W260 | 2015 and newer | --- | --- | --- | --- | X | X | X | X |

| W110 to W170* | --- | --- | X | X | X | X | |||

NOTE: When adding the 4640 Universal Display to a John Deere self-propelled windrower, it will only be compatible as a cornerpost precision ag display.

*NOTE: For 22-2, a virtual windrower option is available to support W110 to W170 Self-Propelled Windrowers. VIN detection is not available on these machines.

NOTE: 24-1 Gen OS Software introduces AutoPath compatibility to the following windrower models: W235 and W260 MY14 and newer machines. model year 2022 and newer machines.

John Deere Gators

John Deere Gators | Model year | CommandCenter Display | Universal Display | ||||||

4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | ||

XUV 845M HVAC | 2025 and newer | --- | --- | --- | --- | X | --- | X | --- |

XUV 845R | 2025 and newer | --- | --- | --- | --- | X | --- | X | --- |

XUV 845R Signature Edition | 2025 and newer | --- | --- | --- | --- | X | --- | X | --- |

XUV 875M HVAC | 2025 and newer | --- | --- | --- | --- | X | --- | X | --- |

XUV 875R | 2025 and newer | --- | --- | --- | --- | X | --- | X | --- |

XUV 875R Signature Edition | 2025 and newer | --- | --- | --- | --- | X | --- | X | --- |

NOTE: John Deere Gators with 24-1 or later GenOS software are AutoPath™ capable.

Equipment compatibility

John Deere planters

SeedStar™ 4HP planters are only compatible with 4600 CommandCenter displays with a version 2 (v2) processor and 4640 Universal Displays. Displays should be running the most current version of tractor applications to be compatible with SeedStar 4HP planter applications. Additionally, dual-display mode is available for use with SeedStar 4HP planter applications, along with Generation 4 Extended Monitor. SeedStar 4HP planters are compatible with no more than two GreenStar Rate Controllers.

The SeedStar 2 configuration below is available only on factory-installed model year 2011 and newer planters and may be field-installed on model year 2009 and 2010 planters. Green PM/PA controllers (factory-installed on model year 2009 and 2010 planters) are not supported with a Generation 4 display.

Service ADVISOR™ is needed to update SeedStar 2, SeedStar XP, and SeedStar 3 HP software. Documentation is not supported when using a rate controller to control row clutches on a John Deere planter.

| John Deere planters | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240* | G5 | G5Plus | |||

| SeedStar 2 | Black PM1 | 22.0 | X | X | X | X | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | X | X | X | X | |

| Green PM1 | 10.11 | --- | --- | --- | --- | --- | --- | --- | --- | |

| Green PA1 (if available PA 2) | 10.11 | --- | --- | --- | --- | --- | --- | --- | --- | |

| SeedStar XP | Black PM1 | 22.0 | X | X | X | X | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | X | X | X | X | |

| PM2 | 7.0 | X | X | X | X | X | X | X | X | |

| SeedStar 3 HP | Planter Main A (PCMA) | 6.0 | X | X | X | X | X | X | X | X |

| Planter Main B (PCMB or MMC) | 8.0 | X | X | X | X | X | X | X | X | |

| Row-unit Controller (RUC) | 2.0 | X | X | X | X | X | X | X | X | |

| EPG | 3.0 | X | X | X | X | X | X | X | X | |

| SeedStar 4HP | Planter Apps | 10.4.332-12 | X | --- | X | X | X | --- | X | X |

| Planter Main A (PMCA) | 6.0 | X | --- | X | X | X | --- | X | X | |

| Planter Main B (PMCB or MMC) | 10.0 | X | --- | X | X | X | --- | X | X | |

| Row-unit Controller (RUC) | 4.0 | X | --- | X | X | X | --- | X | X | |

| Electrical Power Generation (EPG) | 5.0 | X | --- | X | X | X | --- | X | X | |

| Electrical Power Module, 2 (PC2) | 4.0 | X | --- | X | X | X | --- | X | X | |

| ExactRate™ liquid fertilizer system | Master Nozzle Control Unit (MNC) | 2.0 | X | --- | X | X | X | --- | X | X |

| Spray Rate Control Unit (SRC) | 2.0 | X | --- | X | X | X | --- | X | X | |

| Liquid Blockage Controller (LBC) | 2.0 | X | --- | X | X | X | --- | X | X | |

| Nozzle Control Unit (NZC) | 6.04 | X | --- | X | X | --- | X | X | ||

| ExactRate app | 10.1.269-64 | X | --- | X | X | --- | X | X | ||

*NOTE: For implements requiring ground speed input (radar), utilising a 4240 Universal Display may require an additional 4240 radar speed kit.

John Deere Air Seeders

The C650 and C850 Air Carts and N500C Seeder are not supported with a GreenStar 3 2630 Display. Additionally, tow-behind C850 Air Carts are compatible with (passive) AutoTrac™ Implement Guidance (ATIG) with software update 18-2 and newer, and hydraulically-driven tow-between air carts are compatible with ATIG and AutoTrac Turn Automation with software update 24-2 and newer.

| John Deere Air Seeder | Model year/control unit name | Software version (or newer) | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240* | G5 | G5Plus | |||

| C650/850 Air Cart | Cart Master Controller (CMC) | 3.0 | X | X | X | X | X | X | X | X |

| Mini Tank Controller (TCX) | 2.0 | X | X | X | X | X | X | X | X | |

| Front, Middle, Rear Tank Controller (TCU) | 2.0 | X | X | X | X | X | X | X | X | |

| 1870 Seeding Tool - TruSet™ system | 2017 and newer (IDC) | 5.0 | X | X | X | X | X | X | X | X |

| 1870 Seeding Tool - RelativeFlow™ blockage sensors | 2017 and newer (BMU) | 6.0 | X | X | X | X | X | X | X | X |

| 1910 Air Cart - ground drive | 2009 and newer | 3.0 | X | X | X | X | X | X | X | X |

| 1910 Air Cart - hydraulic drive | 2013 and newer | 11.0 | X | X | X | X | X | X | X | X |

| Seeding tools with air-run blockage - primary blockage | 2009 and newer (BMU) | 12.0 | X | X | X | X | X | X | X | X |

| Seeding tools with air-run blockage - air-run blockage | 2009 and newer (BMU) | 12.0 | X | X | X | X | X | X | X | X |

| Member Module | 5.0 | X | X | X | X | X | X | X | X | |

| 1990 Central Commodity System (CCS™) | 2009 and newer (BMU) | 12.0 | X | X | X | X | X | X | X | X |

| N500C Series | Seeder apps | 10.2.19-13 | X | --- | X | X | X | --- | X | X |

| SMCA or SMC | 4.0 | X | --- | X | X | X | --- | X | X | |

| SMCB or BMU | 3.0 | X | --- | X | X | X | --- | X | X | |

| EPG | 3.0 | X | --- | X | X | X | --- | X | X | |

*NOTE: For implements requiring ground speed input (radar), utilising a 4240 Universal Display may require an additional 4240 radar speed kit.

John Deere Tillage

| John Deere Tillage | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | |||

| AccuDepth™ cultivator | Implement Depth Control (IDC) | 11 | X | X | X | X | X | X | X | X |

| 2730 with TruSet | Tillage Controller 1 (TC1) | 2.66K9 | X | X | X | X | X | X | X | X |

| 2230 with TruSet | Tillage Controller 1 (TC1) | 2.75K6 | X | X | X | X | X | X | X | X |

| 2330 with TruSet | Tillage Controller 1 (TC1) | 2.35K6 | X | X | X | X | X | X | X | X |

| 2620/2630 with TruSet | Tillage Controller 1 (TC1) | 2.95K6 | X | X | X | X | X | X | X | X |

| 2720 with TruSet | Tillage Controller 1 (TC1) | 2.24K6 | X | X | X | X | X | X | X | X |

| 2660VT with TruSet | Tillage Controller 1 (TC1) | 3.03K12 | X | X | X | X | X | X | X | X |

| 2430 with TruSet | Tillage Controller 1 (TC1) | 2.14K4 | X | X | X | X | X | X | X | X |

| 2510H with TruSet | Tillage Controller 1 (TC1) | 2.85K5 | X | X | X | X | X | X | X | X |

*NOTE: For implements requiring ground speed input (radar), utilising a 4240 Universal Display may require an additional 4240 radar speed kit.

John Deere Round Balers

| John Deere Round Balers | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | |||

| 0 Series | Baler Automation | 10.07 | X | X | X | X | X | X | X | X |

| 9 Series Premium | Baler Automation | 7.16 | X | X | X | X | X | X | X | X |

| V451R/V461R | Baler Automation | 11.5 | X | X | X | X | X | X | X | X |

John Deere Large Square Balers

| John Deere Large Square Balers Including Harvest Tec applicator and PhiBer accumulator | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | |||

| 0 Series | Gen 4 VT | 3.04 | X | X | X | X | X | X | X | X |

| 1 Series | Gen 4 VT | 5.07 | X | X | X | X | X | X | X | X |

Precision Ag Technology software compatibility

| John Deere control units | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||||||

| 4600 v2 | 4200 | G5 | G5Plus | 4640 | 4240 | G5 | G5Plus | |||

| *StarFire™ 6000 Receiver | --- | 4.50P | X | X | X | X | X | X | X | X |

| StarFire 6000 Integrated Receiver | --- | 4.50P | X | X | X | X | X | X | X | X |

| StarFire 3000 Receiver | --- | 2.80S | X | X | X | X | X | X | X | X |

| *Modular Telematics Gateways (MTG) - 3G | --- | 21.03 | X | X | X | X | X | X | X | X |

| *MTG - 4G | --- | 27.01.541 | X | X | X | X | X | X | X | X |

| GreenStar Rate Controller | --- | 3.70K | X | X | X | X | X | X | X | X |

| GreenStar Rate Controller Dry | --- | 2.11A | X | X | X | X | X | X | X | X |

| *John Deere Rate Controller 2000 | --- | 1.13A | X | X | X | X | X | X | X | X |

| *AutoTrac™ Universal 200 | --- | 2.30A | --- | --- | --- | --- | X | X | X | X |

| *AutoTrac Universal 300 | --- | 3.24L | --- | --- | --- | --- | X | X | X | X |

| AutoTrac Controller 300 | --- | 3.24L | --- | --- | --- | --- | X | X | X | X |

| AutoTrac Controller 250 | --- | 11933B | --- | --- | --- | --- | X | X | X | X |

| *AutoTrac Controller - Deere | --- | 1.11B | --- | --- | --- | --- | X | X | X | X |

| AutoTrac Controller - Raven | --- | 10.13.909-158 | --- | --- | --- | --- | X | X | X | X |

| AutoTrac Controller - Reichhardt® | --- | SW 1.3 | --- | --- | --- | --- | X | X | X | X |

| AutoTrac RowSense | RG3 | AKK15783H | X | --- | X | X | X | --- | X | X |

| AutoTrac Vision | VGC | 4.01V | X | --- | X | X | X | --- | X | X |

| AutoPath™ | --- | 20-3 | X | --- | X | X | X | --- | X | X |

| AutoTrac Turn Automation | --- | 19-3 | X | --- | X | X | X | --- | X | X |

| AutoTrac Implement Guidance (Passive) | --- | 19-3 | X | --- | X | X | X | --- | X | X |

| Machine Sync | --- | 20-3 | X | --- | X | X | X | --- | X | X |

| In-Field Data Sharing | --- | 20-3 | X | --- | X | X | X | --- | X | X |

| Implement Guidance (Active) | UCC2 Application Controller | 2.71Z | X | X | X | X | X | X | X | X |

| UCC2 Application Controller (serial number PCXL01C201000-) | 3.20A | X | X | X | X | X | X | X | X | |

| Idle Reasons | --- | 24-1 | X | --- | X | X | X | --- | X | X |

| iGrade™ | UCC2 Application Controller | 2.71Z | X | X | X | X | X | X | X | X |

| UCC2 Application Controller (serial number PCXL01C201000-) | 3.20A | X | X | X | X | X | X | X | X | |

| Distance Trip | UCC2 Application Controller | 2.71Z | X* | X | X | X | X | X | X | X |

| UCC2 Application Controller (serial number PCXL01C201000-) | 3.20A | X* | X | X | X | X | X | X | X | |

| Yield Documentation, Specialty Crop | UCC2 Application Controller | 1.51Y | X | X | X | X | X | X | X | X |

| UCC2 Application Controller (serial number PCXL02C201000-) | 3.20A | X | X | X | X | X | X | X | X | |

| Mobile Weather | UCC2 Application Controller | 1.51Y | X | X* | X | X | X | X* | X | X |

| UCC2 Application Controller (serial number PCXL02C201000-) | 3.20A | X | X* | X | X | X | X* | X | X | |

| Harvest Identification, Cotton | UCC2 Application Controller | 1.51Y | --- | --- | --- | --- | X | --- | X | X |

| UCC2 Application Controller (serial number PCXL02C201000-) | 3.20A | --- | --- | --- | --- | X | --- | X | X | |

| Earthmoving Productivity System | UCC2 Application Controller | 1.51Y | --- | --- | --- | --- | X | --- | X | X |

| UCC2 Application Controller (serial number PCXL02C201000-) | 3.20A | --- | --- | --- | --- | X | --- | X | X | |

| Gen 4 Extended Monitor | X | --- | --- | --- | X | --- | X | X | ||

| Wireless Data Server | Wireless Data Server | 1.591.2 (Planting) | X | --- | X | X | X | --- | X | X |

| Mobile Data Transfer | MyTransfer™ app | 3.8.6 (iOS®) | X | X | X | X | X | X | X | X |

| Connect Mobile app | Connect Mobile app | 8.4.0 or newer | X | --- | X | X | X | --- | X | X |

| Connect Mobile server | Connect Mobile server | 2.3.113-1 | X | --- | X | X | X | --- | X | X |

| Manure Constituent Sensing | Manure Controller | 19.06 | X | --- | X | X | X | --- | X | X |

*NOTE: See additional information below.

StarFire Receivers

StarFire Receivers can be updated in the following ways:

- Receiver USB port (available only for StarFire 6000 Receivers)

- Generation 4 display USB port

- Remote software updates application (in ISOBUS VT app)

John Deere Operations Center™ application

To use RDA on a Generation 4 CommandCenter Display with a GreenStar 3 2630 Display connected in the same machine, GreenStar 3 2630 software version 3.22.1095 (SU2014-1) or higher is required (for 4600 CommandCenter Display and 4640 Universal Display only).

GreenStar Rate Controller Dry

GreenStar Rate Controller Dry (GDC) 2.11A was the last software version available through Software Manager. GDC 2.20A has been available since spring 2015 and contains diagnostic language updates. This software can only be obtained through Service ADVISOR.

John Deere Rate Controller 2000

The John Deere Rate Controller 2000 will not control the planter clutches or half-, third-, or quarter-width disconnects on a John Deere planter.

AutoTrac Vision

AutoTrac Vision Guidance is only compatible with Generation 4 18-1 software 10.10.404-345 or newer.

ISOBUS implements

Generation 4 and G5 displays support two Agricultural Industry Electronics Foundation (AEF) certified ISOBUS control units. The use of two ISOBUS control units is limited to the configuration of one front and one rear implement. The use of multiple ISOBUS control units as rear implements is not supported. Generation 4 displays support AEF-certified ISOBUS implements with Task Controller Section Control (TC-SC) functionality and AEF certification for TC-SC include sprayers, fertilizer spreaders, planters, seeders, manure applicators, etc. For third-party FMIS compatibility, reference the John Deere Operations Center.

A software update performed by an authorized ISOBUS implement dealer may be required to obtain compatible software. ISOBUS implements must be certified through the Agricultural Industry Electronics Foundation (AEF) to be recognized by the Generation 4 CommandCenter Display. Visit www.aef-online.org for more information; visit www.aef-isobus-database.org for an active list of compatible implements.

ISOBUS implements with VT4 are now supported by G5 and Generation 4 displays. Generation 4 displays still support older VT versions (example: VT2 and VT3). If an implement is not loading after updating to Generation 4 software update 2017-2 (or newer on 4600 CommandCenter v2 processors), it is recommended that the implement manufacturer be contacted to get a software version that is either VT3 or VT4.

Implements without controllers

Implements without controllers can be documented as a stand-alone operation or with a rate controller from John Deere. Additionally, multiple implements without controllers cannot be documented together.

AutoPath

AutoPath is compatible with G5 displays, Gen 4 4600 CommandCenter (v2 server) and 4640 Universal Displays. AutoPath (rows) (20-3 and later software) requires specific row data documentation (that is gathered during the first field operation of the year), using an implement mounted StarFire Receiver equipped with SF3 or higher correction signal. Shared signal is compatible.

For more information on AutoPath functionality and requirements, please refer to the AutoPath Sales Manual.

AutoTrac Implement Guidance (Passive)

- AutoTrac Implement Guidance is compatible with SeedStar 5HP, SeedStar 4HP, SeedStar 3 HP, SeedStar 2, and SeedStar XP.

- AutoTrac Implement Guidance is compatible with N500C seeding tools, 1990CCS Seeders as well as 1910, C650, and C850 Tow-Behind Air Carts.

- AutoTrac Implement Guidance is compatible with C Series and hydraulically driven 1910 Tow-Between Air Carts. (ATIG is NOT compatible with ground-driven Tow-Between Air Carts)

Important Notes:

- Tow-Between and Two-Behind Air Carts are compatible with the following track types:

- Straight tracks

- AB Curve tracks

- AutoPath (rows) and (boundaries) tracks

- Tow-Between and Two-Behind Air Carts are NOT compatible with the following track types:

- Boundary tracks

- Adaptive curve tracks

AutoTrac Turn Automation

AutoTrac Turn Automation is compatible with the following machines:

- 8030 Series Tractors

- 9030 Series Tractors (if equipped with PowerShift™ transmission)

- Model year 2012 and newer 6R Tractors (if equipped with Infinitely Variable Transmission [IVT™] and ITEC™ functionality)

- Model year 2012 and newer John Deere 6R Tractors (with direct drive transmission (non IVT))

- This 6R tractor model is not compatible with speed automation but can utilise automated turn and iTEC functionality (23-3 software or newer required).

- 6M, 6020 and 6030 John Deere Tractors are NOT compatible with ATTA.

- Model year 2011 and newer 7R Tractors (if equipped with CommandQuad™ transmission (CQT), e23™ PowerShift transmission, or IVT)

- Model year 2010 and newer 8R/RT Tractors

- Model year 2012 and newer 9R/RT/RX Tractors

NOTE: Integrated tractor IMS must be turned off on 30 Series Tractors to use AutoTrac Turn Automation on the G5 or Gen 4 display. Integrated Tractor iTEC must be turned off on the following tractors to use AutoTrac Turn Automation on the G5 or Gen 4:

- Model year 2012-2014 6R

- Model year 2011-2013 7R

- Model year 2010-2013 8R

- Model year 2012-2014 9R

NOTE: If instead an operator chooses to use the machine’s integrated IMS/iTEC functionality, then AutoTrac Turn Automation and iTEC must be turned off in the Gen 4 or G5 Display.

AutoTrac Turn Automation is compatible with the following implements:

- SeedStar 5HP, SeedStar 4 HP, SeedStar 3 HP, SeedStar 2, and SeedStar XP planters, 1990CCS Seeders, and 1910, C650, C850 Tow-Behind Air Carts, C Series Tow-Between Air Carts, and 1910 hydraulically driven Tow-Between Air Carts.

- See the "Additional Information" section of DTAC solution 115995 for more information.

AutoTrac Turn Automation is NOT compatible with the following implements and implement configurations:

- Front-mounted implements

- Multiple implements pulled in a series where the equipment doing the work is not connected directly to the tractor, with the exception of Tow-Between Air Carts

For more information on AutoTrac Turn Automation functionality and requirements, please refer to the Sales Manual.

Machine Sync

All machines (leaders and followers) running Machine Sync must be equipped with High Connectivity Machine Sync antennas. This will yield the best performance and connection between the two machines when unloading harvested crops on the go.

Part # BPF12656 : High-connectivity antenna kit for Machine Sync technology utilisation via a Gen 4 or G5 display. This antenna kit is compatible with the following machines:

- MY14 and newer 7 Series Tractors

- MY14 and newer 8 Series Tractors

- MY14 and newer 9 Series Tractors

- MY25 and newer combines:

- X9, S7 Combines configured with a Premium/Ultimate Technology Package | Harvester built These machines are shipped with the antenna from the factory. This kit is only necessary if the original antenna, cable, and bracket needs replaced.

Supported leader platforms

- Combine:

- X Series Combines, S Series Combines, W Series Combines, T Series Combines, 70/60/50 Series Combines

- Self-Propelled Forage Harvesters

- 9000 Series and 8000 Series

- John Deere Tractors

- All models outlined in the follower platform section below.

- John Deere Sugar Cane Harvesters:

- MY24+ CH570W

- MY24+ CH570T

- MY18 – MY23 CH570

- MY18 – MY23 CH670

- MY21+ CH950

- MY21+ CH960

Supported follower platforms

- John Deere tractors (wheeled models)

- 6R with Infinitely Variable Transmission (IVT™) (iTEC™ functionality required)

- 7R with CommandQuad™ Eco transmission, e23™ transmission, and IVT

- 8030 with PowerShift™ transmission and IVT

- 8R with PowerShift, IVT, and e23 transmission

- 9030 with PowerShift transmission

- 9R with PowerShift transmission with Efficiency Manager™ feature

- John Deere tractors (tracked models)

- 8RT/8RX with PowerShift, IVT, and e23 transmission

- 9RT/9RX with PowerShift transmission with Efficiency Manager feature

NOTE:

- John Deere 8030T and 9030T models are not compatible with Machine Sync.

- Reference DTAC Solution 23RW997 to update tractor transmission software.

Machine Sync is supported on G5/G5Plus Universal or CommandCenter Displays, Gen 4 4600 CommandCenter Displays, and Gen 4 4640 Universal Displays. G5 and Gen 4 configurations will work with one another. I.E., an X9 Combine is equipped with a G5 Plus Display, and its grain cart tractor is equipped with a Gen 4 display will work together in a Machine Sync setting.

We recommend the leader has a higher or equal correction signal to the follower. Starting May of 2024, StarFire 3000 Receiver software updates and fixes will no longer be available, therefore, this receiver will no longer be compatible with Machine Sync. The configuration will not be blocked; however, support will be discontinued in the event an issue arises.

Idle Reasons

Idle Reasons is available with the following activations/subscriptions: Premium 3.0, Automation 4.0 or G5 Advanced with 24-1 or later software.

Reprogramming UCC2 Application Controllers

4600 CommandCenter v1 does not support reprogramming on the UCC2 version of Application Controller. Service ADVISOR or compatible displays may be used.

Distance Trip documentation/Yield Documentation, Specialty Crop

A UCC2 Application Controller with 19-2 software or newer, running on a 4600 CommandCenter v2 server enables documentation of field operations. If a UCC2 replaces a UCC1 Application Controller on a CommandCenter v1 server, documentation is not available.

Camera compatibility

Voyager® cameras are supported on Generation 4 displays. All other camera types are not supported.

Non-John Deere Precision Ag

4600 CommandCenter v2 and the 4640 Universal Display are compatible with the following RS-232 configurations with software update 18-2 and newer:

- Global positioning system (GPS) receivers with serial port connection

- Will not enable AutoTrac guidance functionality

- Raven RS-232 control units (440, 450, or 660) on tractors configured as implement-based applications

- Generation 4 displays are not compatible with the DN345 Drawn Dry Spreader at this time.

4600 CommandCenter v2 and the 4640 Universal Display are compatible with the following RS-232 configurations with software update 20-3 and newer:

- Yara N-Sensor

- Fritzmeier

- Trimble® GreenSeeker®

- LH 5000

Machine Communication Radio (MCR)

Generation 4 displays are not compatible with MCR.

NOTE: Gen 4 data is only compatible with the John Deere Operations Center. All Gen 4 activations are machine specific and cannot be transferred to a different machine. If not using WDT, an 8- to 32-GB USB is required to transfer data to and from the Gen 4 display. Implement settings are display specific and cannot be imported or exported from the Gen 4 display.

RAM is a trademark of National Products Inc. Montag is a trademark of Montag Manufacturing, Inc. Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will support Hagie equipment. Reichhardt is a trademark of Reichhardt GmbH Steuerungstechnik. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc. Android is a trademark of Google LLC. Voyager is a trademark of ASA Electronics, LLC. Trimble and GreenSeeker are trademarks of Trimble, Inc.