- 37.3 kW (49.6 hp) 2.9 L PowerTech™ 3-Cyl Tier 3 engine

- Standard 9F/3R Top Shaft Synchronised (TSS) Transmission

- Category 2, 3-point hitch, 2,000 kg max. lift capacity (at ball joint)

- 540 Standard and 540 Economy Power Take Off (PTO)

Features

Prevent temporary overload with high backup torque

The 5E engines are designed with high torque reserve of around 20-25 percent.

Backup torque is the ability of the machine to keep working as the engine pulls down due to increased load requirements over and above the maximum power.

This backup torque prevents temporary overload, and frequent gear shifting during haulage and tillage applications, thus reducing operator fatigue.

| Model | Cylinders | Engine displacement | Engine power | PTO power | Rated rpm | Aspiration |

| 5050E | 3 | 2.9 L | 37.3 kW (50 hp) | 31.8 kW (42.6 hp) | 2400 | Turbocharged |

Top-shaft synchronised transmission

The 5E Series Tractor lineup offers the reliable nine-forward/three-reverse (9F/3R) top-shaft synchronised transmission. The concept of the proven 5E Series transmission provides:

- A wide choice of transmission speeds

- Easy and comfortable shifting

- A reliable, field-proven design made by John Deere

- High efficiency and reduced power losses

- A value-spec transmission

- A competitive price

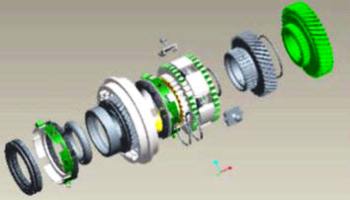

Top-shaft synchroniser

Top-shaft synchroniser

Top-shaft synchroniserAll 5E Series Tractors are fitted with the latest generation of soft-shift transmissions that can be shifted easily even by inexperienced tractor drivers.

What makes this soft-shifting possible is the top-shaft synchroniser. It equalises the speeds of mating gears to allow a clash-free shift while the tractor is in motion.

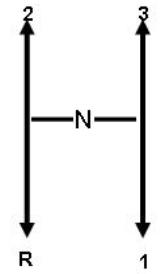

Inline shifting

Inline shifting

Inline shifting Gear lever positioned close to the SCV joystick

Gear lever positioned close to the SCV joystickQuick-reverse manoeuvres during loader work or at the headland can be performed easily with unique inline shifting.

For inline shifting, second gear is positioned directly on the opposite side of the gear lever, so that the operator can change from the second forward gear into the reverse gear in one line. The second forward gear and the reverse gear have the same speed, which means that inline shifting can be used like a reverser. Due to the top-shaft synchroniser, this integrated reverser solution can be shifted softly.

The gear lever is positioned close to the selective control valve (SCV) joystick in order to change quickly between them when operating the implement or front loader during reversing:

Side-shift levers

Side-shift levers

Side-shift leversComfortable shifting without leaning forward—that is only one of the advantages of the side-shift levers. The range lever is conveniently located on the left hand of the operator. The gear lever is placed on the right-hand side to intuitively find the appropriate gear and range. All gear levers are colour coded in orange for quick familiarisation for inexperienced drivers.

Gear shifting

Gear shifting

Gear shiftingThe gear-shifting lever is ergonomically placed within a hand's reach, which is ideal for the operator. The forward gears and one reverse gear can be shifted in short, crisp lever movements. When in neutral, the gear lever automatically goes into the slot between the second and third gear, which makes shifting very convenient, especially when travelling on a road when gears need to be shifted quickly.

All gears are synchronised.

Range shifting

Range shifting

Range shiftingThree ranges are provided to always find the perfect gear for each single application. High-contact helical gears provide large-tooth contact for great torque transmission capability and quiet operation.

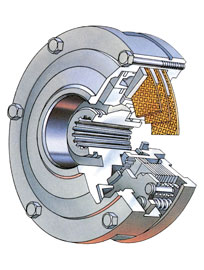

PermaClutch 3 reduces service and maintenance costs

PermaClutch 3

PermaClutch 3PermaClutch is back. Hydraulic, wet, forward, and reverse clutches are permanently lubricated by cooled oil to maximise durability for the long life of a tractor.

The operator does not have to service the PermaClutch 3 on the tractor after 5000 to 6000 hours, which is the average service interval for a dry clutch disc change.

This results in less service and maintenance costs.

Dual clutch

Dual clutch

Dual clutchReliable and field-proven dual clutches are used in 5E Tractors, one for the power take-off (PTO) and one for driving. The dual clutch ensures independent operation of the PTO, which ensures that the PTO can keep running when the driving clutch is disengaged. This ensures enhanced productivity.

All 5E Series Tractors feature a dry design clutch with a diameter of 280 mm.

Standard and economy PTO

Standard and economy PTO

Standard and economy PTOAll 5E Tractors have the 540 Standard and 540 Economy PTO as standard. The 540 Economy PTO can be driven at only 1705 engine rpm. This allows lower fuel consumption and lower noise emissions, and is more cost efficient. The 540 standard PTO is driven at 2400 engine rpm.

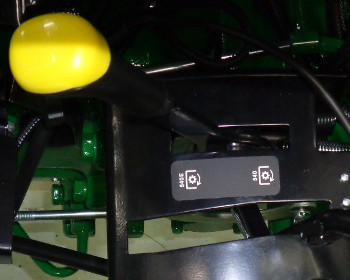

Quick-headland power take-off (PTO) control

Electro-PTO engagement and disengagement on headlands

Electro-PTO engagement and disengagement on headlandsTogether with the electro-reverser, there is also a electro-PTO engagement available. This means when the operator reaches end of field with tiller, the operator just needs to fingertip a soft-push button, which is located close to the raise-lower lever, so the operator can manoeuvre controls quickly for tournament.

Save fuel, reduce noise, and increase engine life in power take-off (PTO) applications with the 540/540 economy PTO

PTO lever

PTO lever Dual PTO lever

Dual PTO leverThe 540/540 economy PTO allows operators to select the engine rpm for reduced fuel consumption, reduced noise levels, reduced vibration, and less wear and tear on the engine, while at the same time keeping the proper 540 rpm at the PTO.

The economy PTO provides 540 rpm to the PTO at 1705 engine rpm. The 540 economy mode is ideal for any PTO applications where full engine horsepower is not required.

Operating at lower engine rpm decreases fuel costs up to 30 percent and provides additional productivity by improving the operating experience through enhanced operator comfort from reduced noise and vibration.

A lever allows the operator to simply change between 540 and 540E when conditions merit the opportunity to save fuel without affecting performance.

For heavy-duty operations requiring maximum PTO power, the PTO shift lever is placed in the 540 position, the PTO is engaged, and the engine is run at a rated speed of 2400 rpm. This selection gives 540 rpm to the PTO shaft and delivers the fully advertised horsepower at rated engine speed.

When the tractor is in economy PTO mode, the engine is electronically limited to 1705 rpm, preventing accidental over-speeding of PTO implements and protecting against binding the PTO shaft.

This interlock also prevents accidental shifting of the PTO selector lever at engine speeds above 1700 rpm, which would lead to downtime for fixing implements or drivetrain components.

Straddle-mount design – A spacious open-station platform for comfort and convenience

5050E Tractor straddle-mount operator

5050E Tractor straddle-mount operatorThe 5050E Tractor straddle-mount operator station is designed to position the operator farther forward and slightly lower. This design improves the operator's ride and visibility.

Platform-mounted shift levers and suspended clutch and brake pedals contribute to a clean platform design. Suspended pedals also make it easier for the operator to get on and off the tractor, and make clutch operation easier on the operator when the tractor is used in applications requiring the pedals to be used frequently, such as loader work.

Deluxe seat

Deluxe seat

Deluxe seatA deluxe seat is standard to provide a comfortable ride. The seat is suspended by two springs with a hydraulic dampener. A mid-ride indicator allows the operator to optimize seat comfort.

The operator can adjust the seat up and down along an inclined rail by using a lever located to the right and under the seat. The suspension adjusts to the operator's weight.

Toolbox

Toolbox

ToolboxAll 5050E Tractors come standard with storage locations for tools, parts, and operator's manuals. The toolbox is conveniently located on the left fender for easy access to tools and spare parts that may be needed in the field. It is made from a weather-resistant, durable plastic material.

Steps and handrails

Steps

Steps Handrail

HandrailEnter and exit the operator’s station with ease. To enhance access to the operator's station, left-side steps are standard equipment on all 5050E Open Operator Station (OOS) Tractors.

Handrails provided on either side (with heat shield and on fenders) allow 3-point comfortable contact for the operator for easy enter and exit.

Oil-immersed disc brakes provide durability and long life

Wet-disc brakes

Wet-disc brakesOperators can expect sure stops when the unexpected happens in the field, on the highway, or at home with hydraulic wet-disc brakes.

The brake pedals can be locked together for braking action on both rear wheels when in transport or they can be unlocked to make tighter turns in the field.

The brakes are oil cooled for maximum performance throughout the life of the tractor.