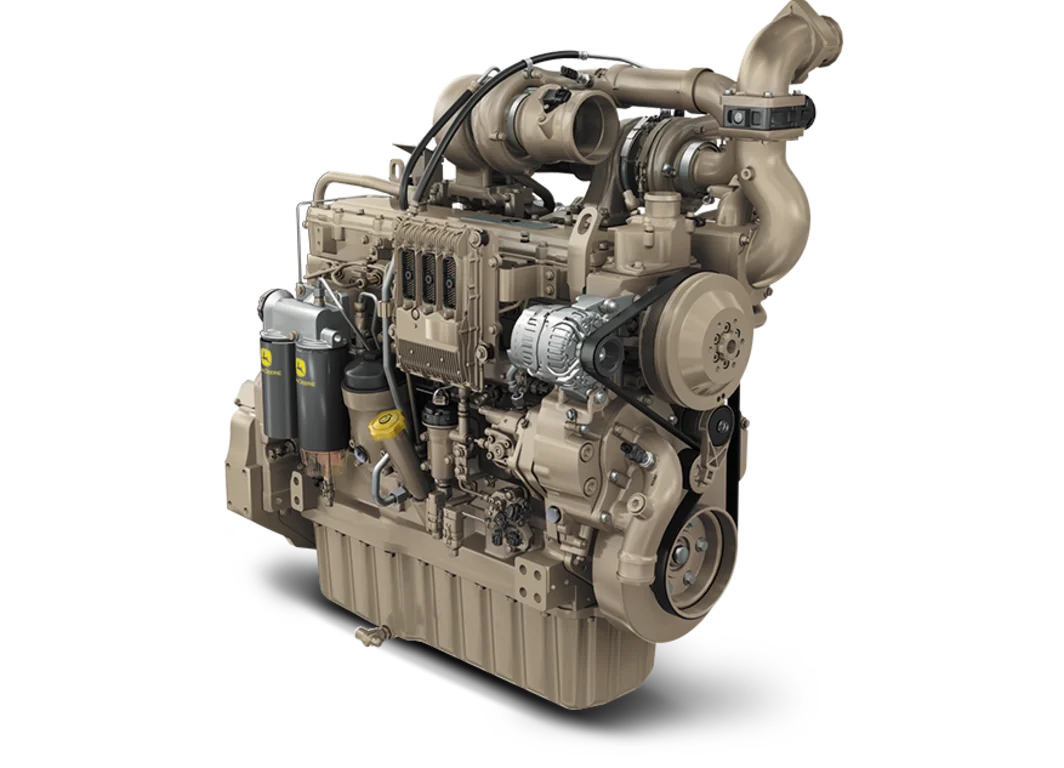

6068HFG95

6.8L Generator Drive Engine

Nothing Runs Like a Deere™

- PowerTech™ PSX

- Standby: 216 kW (289 hp) @ 1800 rpm

- Prime: 215 kW (288 hp) @ 1800 rpm

X

Select Your Closest Emmetts Branch and Ask About This Machine Today!

Features

Meet emissions requirements without sacrificing performance with the 216 kW (289 hp) John Deere 6068HFG95 Interim Tier 4 generator drive diesel engine with mechanical fuel systems.

Expand All

Series turbocharger

- Fresh air is first drawn into the low-pressure turbocharger (fixed geometry) and compressed to a higher pressure. The compressed air is then drawn into the high-pressure turbocharger (VGT), where the air is further compressed. The high-pressure air is then routed through a charge air cooler and into the engine’s intake manifold.

- By splitting the work between two turbochargers, both can operate at peak efficiency and at slower rotating speeds — lowering stress on turbocharger components and improving reliability. Series turbocharging delivers more boost pressure than single turbocharger configurations, which results in higher power density, improved low-speed torque, and improved high altitude operation.

Cooled exhaust gas recirculation (EGR)

- EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing NOx.

Exhaust filters

- These engines utilize a catalyzed exhaust filter that contains a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF). The DOC reacts with exhaust gases to reduce carbon monoxide, hydrocarbons, and some particulate matter (PM). The downstream DPF traps and holds the remaining PM. Trapped particles are oxidized within the DPF through a continuous cleaning process called passive regeneration.

- Passive regeneration occurs during normal operating conditions when heat from the exhaust stream and catalysts within the exhaust filter trigger the oxidation of the trapped PM. If passive regeneration cannot be achieved due to low temperature, load, or speed, then PM is removed using active regeneration — an automatic cleaning process controlled by the exhaust temperature management system. Engines below 130 kW (174 hp) use an in-cylinder dosing system for active regeneration, while larger engines use an external dosing system.

High-pressure common-rail (HPCR) and engine control unit (ECU)

- The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures up to 1,975 bar (29,000 psi). It also controls fuel injection timing and provides precise control for the start, duration, and end of injection.

Electronic unit injector

- The EUI fuel system provides higher injection pressures up to 2,275 bar (33,000 psi). It also controls fuel injection timing and provides precise control for start, duration, and end of injection.

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow by utilizing a cross-flow design.

Air-to-air aftercooled

- This is the most efficient method of cooling intake air to help reduce engine emissions. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

Compact size

- Lower installed cost; simplifies installation; mounting points are the same as previous engine models

Engine performance

- Faster engine control unit (ECU) manages both the engine and the exhaust filter; full authority electronic controls; four times the memory, twice the RAM, and double the processing speed; the input/output capability has increased 40%

Additional features

- Glow plugs

- 500-hour oil change

- Self adjusting poly-vee fan drive

- Variable-speed fan drive increases fuel economy and decreases noise levels

- R.H. and L.H. engine-mounted final fuel filters

- Low-pressure fuel system with electrical transfer pump and "auto-prime" feature

- Directed top-liner cooling

Specifications

Expand All

Emissions Certifications

- CARB

- EPA Interim Tier 4

General Engine Data

- Model

- 6068HFG95

- Number of cylinders

- 6

- Displacement-- L (cu in)

- 6.8 (415)

- Bore and Stroke-- mm (in)

- 106 x 127 (4.17 x 5.00)

- Compression Ratio

- 17.2 : 1

- Engine Type

- In-line, 4-cycle

- Aspiration

- Turbocharged and air-to-air aftercooled

- Length - mm (in)

- 1161 (45.7)

- Width-- mm (in)

- 767 (30.2)

- Height-- mm (in)

- 1144 (45.0)

- Weight, dry - kg (lb)

- 785 (1731)

Doc/Dpf Dimensions

- Size NA - Diameter - mm (in)

- 320.5 (12.6)

- Size NA - Length - mm (in)

- 891.9 (35.1)

- Size NA - Weight - kg (lb)

- 30 (66.1)

Performance Data Range

- Hz (rpm)

- 60 ( 1800 )

- Generator Efficiency %

- 89-93

- Power Factor

- 0.8

- Engine power - Prime kW

- 196

- Engine power - Prime hp

- 263

- Engine power - Standby kW

- 216

- Engine power - Standby hp

- 290

- Rated Fan Power - kW

- 13

- Rated Fan Power - hp

- 17.4

- Calculated generator set output - Prime kWe

- 164-172

- Calculated generator set output - Prime kVA

- 205-215

- Calculated generator set output - Standby kWe

- 181-189

- Calculated generator set output - Standby kVA

- 226-236

Copyright 2024 Emmett Motors.